About this product

Advantage

Use

Substrates

Preparation of substrates

Instructions for use

Indicaciones importantes

Technical data

Cleaning tools

Descriptive memory

Seguridad e Higiene

Certifications

About this product

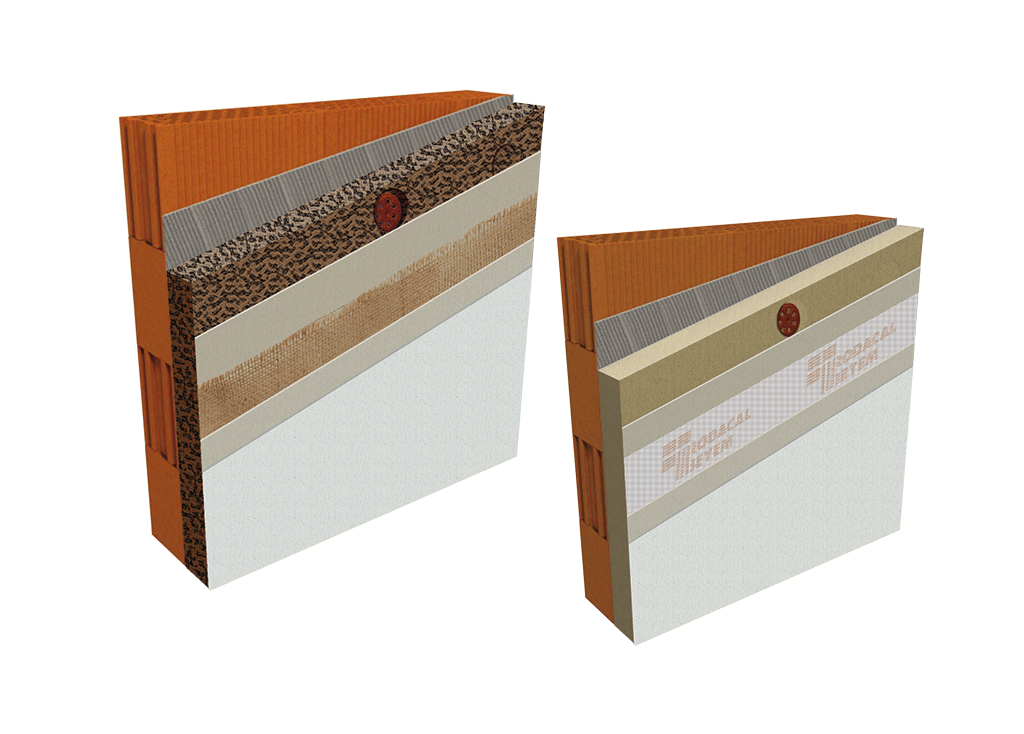

SATE BEYEM ECOTERM is an external thermal insulation system for facades based on the use of natural materials for all the main components of the system: cork/wood as insulation material (ICB/WF), NHL natural hydraulic lime as fixing and facing mortar, air lime/cork as finishing mortar, including protection mesh (jute).

Advantage

- Natural ETIC system.

- The most environmentally friendly solution.

- Natural bacteriostatic and fungistatic.

- Impermeable to rainwater.

- High permeability to water vapour.

- Reduction/elimination of the risk of condensation and interior mould.

- Perfect solution for façade pathologies.

- Ideal for refurbishment. No loss of usable surface area in the home.

Use

SATE BEYEM ECOTERM is intended for use as thermal insulation on the outside of building walls. The walls can be made of masonry (brick, block) or natural materials (wood, cork, ….). The system is designed to provide the facing on which it is installed with satisfactory thermal insulation. This SATE/ETICS can be used on vertical surfaces, both in new construction and in renovation. It can also be used on inclined or horizontal surfaces that are not exposed to rainwater. The system consists of non-load-bearing elements. The system does not contribute directly to the stability of the wall on which it is installed, but contributes to its durability by protecting it against natural agents.

Substrates

The useful substrates for the application of SATE BEYEM ECOTERM, both in new buildings and in refurbishment, are as follows:

In new construction:

- Brick or ceramic block masonry and thermo-clay masonry.

- Mortar rendering.

- Concrete block.

- Treated wood.

- Mortar rendering.

- Single-layer cladding.

- Facing brickwork.

- Stone masonry, mixed walls.

- Treated wood.

Preparation of substrates

The aforementioned substrates must be sound, clean, free of paint residues, poorly adhered parts or substances that may hinder adhesion. All substrates must have adequate flatness and present a surface of adequate porosity and roughness. The substrate must not have clear problems of dampness and, where applicable, must have completed its curing shrinkage and its maturing period must have been respected. Weak, damaged or deteriorated concrete and, where necessary, sound concrete must be removed by suitable manual or mechanical means that do not cause vibration or impact. Heavily deteriorated substrates should be treated by sandblasting or similar method until a surface with minimum guarantees of roughness and tensile strength is obtained. In case of heat, wind or on very absorbent substrates, it is advisable to moisten the substrate and wait for the water film to disappear.

In general, the substrates must have adequate strength to support the coating (minimum adhesion of 0.15 MPa in a pull-off test).

The admissible tolerances of the substrate are as follows:

Instructions for use

System start-up

The system can start above ground level or below ground level giving continuity to the thermal insulation system of the buried walls.

Start-up above ground level: SATE BEYEM ECOTERM must be limited in its contour by an aluminium start-up profile appropriate to the thickness of the insulation board to be used. The starting profile must be positioned at least ≥ 15 cm from the ground, so that the system does not come into direct contact with the ground. Likewise, it must be waterproofed from ground level up to ≥ 30 cm in height, using BEYEM PROOF FLEXIBLE or BEYEM PROOF ONE, to avoid damp due to filtration or capillary action from the outside. The waterproofing must be at least 15 cm above the level of the starting profile.

Start-up of the system below ground level: In this case, an XPS insulation panel with a thickness less than the thickness of the insulation panel used in the system shall be installed initially. This insulation board shall be buried and must protrude ≥ 15 cm above ground level. The starter profile shall be placed on top of the XPS panel, leaving a separation joint between the starter profile and the XPS panel of approx. 2-5 mm, which shall be sealed with polyurethane. Likewise, the aforementioned shall be taken into account with regard to the waterproofing (starting from ≥ 15 cm below the starting profile of the panels) and the finishing of the same.

Laying of insulating panels

The insulation boards should be installed from the bottom upwards and with a joint-breaker, with each row of boards resting on the previous one, except for the first row, which rests directly on the starting profile. At the corners, the ends of the panels should alternate. There are two different laying techniques depending on the planimetry of the substrate:

Edge and point fixing: used on substrates with irregularities of between 5 and 10 mm (measured with a 2 m ruler) and for panels with a thickness ≥ 40 mm. The contact surface with the substrate shall be at least 80%. To do this, BEYEM BIOTERM is placed on the slab in a perimeter bead 4 – 8 cm wide and 2 – 4 cm thick, about 2 cm from the edge of the slab and also in the centre, where several pinches of adhesive mortar with a diameter of 8 – 10 cm are applied.

The minimum final thickness of application as adhesive shall be ≈ 2 mm and a maximum of ≈ 5 mm.

Fixing by means of a notched trowel: it is used when the flatness of the substrate is less than 5 mm measured with a 2 m ruler and for panels < 40 mm. Beyem Bioterm is spread over the entire surface of the board, keeping about 2 cm of the board edges free, and then combed with the help of a notched trowel of at least no. 10.

Mechanical fixing of insulation boards

At least 24 hours after the boards have been adhered, additional mechanical fasteners must be installed, using anchor plugs in a minimum quantity of 6 units per m2 and 8 units per m2 for heights of more than 25 metres. The fixings shall be placed on the perimeter and in the centre of the slabs.

Installation of reinforcement profiles

The corners and edges of existing BEYEM ECOTERM BEYEM SHEATHING openings must be protected and reinforced by using reinforcing profiles. These should be installed at least 24 hours after the panels have been fixed. The most common singular points are usually:

Facade corners, windows and doors: PVC corner profile with fibreglass mesh is used. A layer of BEYEM BIOTERM is applied to the surfaces that form the corner, spreading it along the profile and the mesh, and then the profile is placed, pressing it gently. The protruding mortar is used to cover the mesh and the profile and to even it out.

Window lintel and window sill: Window lintels should be reinforced with the PVC drip profile with mesh to prevent water run-off on the facade planes. The installation method is identical to that of the PVC corner profile with mesh.

The sills must have a minimum outward slope of 10° to ensure water drainage. They must also have an overhang in the horizontal plane of approx. 3-4 cm with a drip edge overhanging the plane of the façade enclosure. The self-adhesive PVC window frame profile with fibreglass mesh allows the SATE to be connected to the frames of the window structure openings without leaving gaps or spaces.

Top finish and expansion joints: The top finish of the façade must prevent water from running directly onto the façade. For this purpose, the crowning profile must be used and screwed in the same way as the starting profile. This profile should be installed before the last row of insulation boards and should overhang the horizontal plane by 3-4 cm. The upper part of the meeting point of this profile and the support where it is fixed must always be protected (by the eaves of the façade or overhang, another profile, polyurethane…).

Expansion joints are resolved by using the PVC expansion joint profile with fibreglass mesh. The installation method is identical to that of the PVC corner profile, except that in this case there is a double edge. The strip contained in the profile is inserted into the expansion joint and then the cover of this profile is inserted.

Treatment of singular points

There are a series of singular points on the façade that must be reinforced with Beyem jute mesh/Beyem fibreglass mesh. These reinforcements should be installed at least 24 hours after the insulating panels have been fixed.

The singular points to be reinforced are:

- Corners of façade openings (windows, doors, …): 20×40 cm strips are cut and fixed with BEYEM BIOTERM at all corners (at 45o) or the corner reinforcement mesh is used (pre-cut mesh).

- Accessible areas exposed to impact (plinths): In the area to be reinforced, BEYEM BIOTERM is spread over the insulation panels. The jute/fibreglass mesh is then spread horizontally and embedded in the mortar. This layer must be at least 1.5-2 mm thick. The joints between the meshes must overlap by at least 10 cm. The installation of this reinforcement mesh shall be additional to the installation of the main mesh.

Indicaciones importantes

- Do not apply BEYEM BIOTERM or BEYEM NEOCAL TERM below 5°C or above 30°C.

- Do not apply the system on horizontal or inclined surfaces, with an angle of inclination of less than 45o.

- Do not apply when there is a risk of frost, rain or strong winds.

- Do not apply BEYEM BIOTERM on plaster, paint, metal surfaces, plastic, waterproofed surfaces and materials with low mechanical resistance.

- Avoid direct sunlight during the application of BEYEM BIOTERM and BEYEM NEOCAL TERM.

- During the installation of the system, it is advisable to protect the façade with protective tarpaulins placed on the scaffolding. It is particularly important to protect the upper part of the façade so that water does not leak between the substrate and the insulating panel, during and after installation.

- Respect the existing expansion joints in the façade and resolve them by using Expansion Joint Profile. Observe the execution of cut-outs, if necessary.

- The age of the substrates in new construction must be at least 1 month in ceramic brickwork and 2 months in concrete blockwork.

- The use of compatible materials and components recommended and supplied by Rodacal Beyem is essential to guarantee the quality of the system.

- The work must be carried out by qualified personnel, with appropriate advice and supervision.

- Carefully read the Technical Product Data Sheets of the materials that make up the system.

Technical data

| ETIC BEYEM ECOTERM |

| Water absorption | |

|

< 1 kg/m² |

|

< 0,5 kg/m² |

| Water vapour permeability | < 1 m (equivalent air thickness) |

| Impact strength | Category II |

| Adherence | |

| Adhesive on the substrate | |

|

≥ 0,25 MPa |

|

≥ 0,08 MPa |

|

≥ 0,25 MPa |

| Adhesive on the insulation | |

|

≥ 0,08 MPa |

|

≥ 0,03 MPa |

|

≥ 0,08 MPa |

| Base layer on top of the insulation | |

|

≥ 0,08 MPa |

|

≥ 0,08 MPa |

| Natural Pressed Cork Insulation | |

| Thickness | 10-60 mm |

| Thermal conductivity | 0,045-0,049 W/mK |

| Density | ±170 Kg/m3 |

| Expanded Natural Cork Insulation | |

| Thickness | 20-250 mm |

| Thermal conductivity | 0,040 W/mK |

| Density | ±110 Kg/m3 |

| Wood Fibre Insulation | |

| Thermal conductivity | 0,037-0,048 W/mK |

| Density | 110 – 265 Kg/m3 |

| Beyem Bioterm | |

| Compression strength | ≥ 6,0 MPa |

| Minimum adhesive application thickness (final) | ≈ 2 mm |

| Maximum application thickness as adhesive (final) | ≈ 5 mm |

| Minimum thickness of application as coating | ≈ 3 mm |

| Maximum thickness of application as a coating | ≈ 5 mm |

| Performance | ≈ 1,25-1,75 Kg/m2 mm of thicknessv |

| Beyem Neocal Term | |

| % Mixing water | ±22% |

| Performance | ≈ 1,4 Kg/m2 |

| Thickness | 4 – 6 mm |

| Compression strength | ≥3,5 MPa |

Cleaning tools

Tools are easily cleaned with water before BEYEM BIOTERM or BEYEM NEOCAL TERM have hardened. Cured or hardened product can only be removed by mechanical means.

Descriptive memory

The façade will be finished with BEYEM ECOTERM SATE, consisting of: natural insulating material boards (ICB/WF), thermal conductivity 0.040 – 0.049 W/mK and Euroclass E reaction to fire and thickness _____. The boards shall be laid horizontally, from bottom to top and at a break in relation to the previous row. The fixing and coating of insulation boards shall be carried out with Beyem Bioterm polymer modified and shrinkage-compensated mortar, covering a minimum of 80% of the adhesion surface of the insulation board. The adhesion of the boards will be complemented with anchor plugs according to EAD 330196-00-0604 at a rate of at least 6 dowels per m2, increasing to at least 8 dowels per m2 at heights of more than 25m. Subsequently, the insulation boards shall be covered with Beyem Bioterm reinforced with 135 g/m2 jute mesh or 160 g/m2 alkali-resistant glass fibre. The yield shall be ≈ 1.25-1.75 kg/m2 mm thickness. Subsequently, Beyem Neocal Term finish coating shall be applied in colour ________________ and texture finish _________. The performance will be ≈ 1.40 Kg/m2 mm thick. Specific profiles are included to treat corners, lintels, changes of plane, expansion joints, joints, jambs, trims and other façade elements.

Seguridad e Higiene

For any information concerning safety issues in the use, handling, storage and waste disposal of chemical products, users should consult the most recent version of the MSDS of the products involved in this Data Sheet. Disposal of the products and their containers must be carried out in accordance with current legislation and is the responsibility of the final consumer of the products.

Certifications

Reviews

There are no reviews yet.